What is an infrared sensor?

Infrared sensor is a sensor that uses infrared rays to measure temperature, analyze gas composition or perform non-destructive testing. It is a non-contact measurement method. Infrared sensor includes optical system, detection element and conversion circuit. Optical system can be divided into transmission type and reflection type according to different structures. Detection element can be divided into thermal detection element and photoelectric detection element according to working principle.

What does an infrared sensor consist of?

Infrared sensors usually consist of three parts: optical system, detection element and conversion circuit.

Optical system: responsible for receiving and focusing infrared radiation and guiding it to the detection element. The optical system usually consists of lenses, filters, etc., which are used to improve the sensitivity and anti-interference ability of the sensor.

Detection element: It is the core part of the infrared sensor and is responsible for converting the received infrared radiation into electrical signals. There are many types of detection elements, including thermocouples, thermistors, photodiodes, photomultiplier tubes, etc. Different types of detection elements have different characteristics and applications.

Conversion circuit: amplifies, filters and converts the electrical signal output by the detection element, and finally outputs a signal that can be used by the circuit or system. The design of the conversion circuit is very important for the performance of the sensor.

How does infrared sensor work?

The working principle of infrared sensors is mainly based on the following effects:

Thermoelectric effect

Thermoelectric effect is the electromotive force generated when there is a temperature difference between two different materials. When infrared radiation is irradiated to the target surface, the target surface absorbs the radiation and is heated, causing the surface temperature to rise. Thermocouples measure this temperature difference and calculate the temperature of the target surface. This principle has been widely used in infrared temperature sensors, which can realize long-distance, non-contact temperature measurement.

Photoelectric effect

The photoelectric effect refers to the interaction between photons and matter, which causes the matter to absorb the photon energy and release photoelectrons. In infrared sensors, the photoelectric effect is usually used to measure the reflectivity and transmittance of the target surface. After the infrared light emitted by the transmitter encounters the object, part of the reflected light is received by the receiver and converted into an electrical signal. By measuring the intensity of the reflected light, the existence, distance and surface characteristics of the object can be judged. The photoelectric effect is mainly used to make devices such as photodiodes and photomultiplier tubes, which are widely used in infrared imaging, spectral analysis and other fields.

Pyroelectric effect

The pyroelectric effect is that some crystalline materials will produce electrical polarization when the temperature changes, thereby generating a voltage signal. In infrared sensors, the pyroelectric effect is used to measure the emissivity of the target surface. When the infrared radiation emitted by the target surface passes through the crystal, the electrical polarization of the crystal changes and generates a voltage signal. By measuring this voltage signal, the emissivity of the target surface can be determined, and then the properties and temperature distribution of the target surface can be analyzed.

What are the types of infrared sensor?

1. Pyroelectric infrared sensors

The core component of the pyroelectric infrared sensor is the pyroelectric detection element. It is made by plating metal electrodes on both sides of the pyroelectric crystal and then polarizing it. This detection element is equivalent to a flat plate capacitor with a pyroelectric crystal as the dielectric. When exposed to infrared light of non-constant intensity, the temperature change of the detection element causes the charge density of its surface electrode to change, thereby generating a pyroelectric current. The pyroelectric infrared sensor responds very sensitively and can detect infrared temperature changes.

2. Thermopile infrared sensors

Infrared thermopile sensor is a sensor that can detect infrared radiation in the surrounding environment. It uses the thermoelectric effect to convert infrared radiation into electrical signals. The sensor usually consists of an integrated circuit chip, an infrared detector and a lens. It can detect infrared radiation emitted by people, animals and objects, realize non-contact temperature measurement and long-distance monitoring. Infrared thermopile sensors have the advantages of fast response speed, high accuracy and long service life.

3. Infrared gas sensors

Infrared gas sensor is a device that uses the principles of infrared absorption, scattering, transmission and reflection to measure gas concentration. It determines the gas concentration by emitting infrared light through the gas being measured and measuring the intensity of the remaining infrared light after transmission. Infrared gas sensor is an optical sensor because it uses the optical principle of infrared light to measure gas concentration. However, it is different from general optical sensors because it measures the intensity of infrared light instead of visible light.

4. Infrared imaging sensors

This sensor is a device that uses infrared thermal imaging technology to measure the temperature distribution on the surface of an object. It can convert the infrared radiation emitted by the surface of an object into electrical signals, and generate corresponding temperature images by analyzing the intensity and distribution of these electrical signals. There are many types of infrared thermal imaging sensors, among which the most commonly used is the infrared thermal imaging sensor based on focal plane array (FPA) technology. Infrared thermal imaging sensors can intuitively display the temperature field on the surface of an object, are not affected by strong light, and are widely used.

5. Active infrared sensors

Active infrared sensor can actively emit infrared beams and detect the presence of targets by detecting the reflection of the beam. When a person or object passes through the infrared beam between the transmitter and the receiver, the infrared signal received by the receiver will change, thus triggering an alarm. This type of infrared sensor is not affected by environmental factors and has more accurate measurements.

6. Fiber optic infrared sensors

Fiber optic infrared sensor is a device that uses fiber optic technology combined with infrared detection technology. It is mainly used to detect and measure physical quantities such as infrared radiation, gas composition and temperature changes. The working principle of this type of sensor is based on the change of specific absorption wavelength and intensity of infrared radiation on the substance. The optical fiber transmits the infrared signal to the detector for analysis. Fiber optic infrared sensors are not affected by electromagnetic interference and are particularly suitable for use in strong electromagnetic environments.

7. Miniature infrared spectrometers

A miniature infrared spectrometer is a device that can use infrared spectroscopy technology to analyze and detect substances. Its main features are small size, low power consumption, and fast response. It usually obtains information by analyzing the absorption characteristics of substances to infrared light of a specific wavelength. It is widely used in gas detection, environmental monitoring, food safety, medical diagnosis and other fields.

How to build a simple infrared sensor circuit?

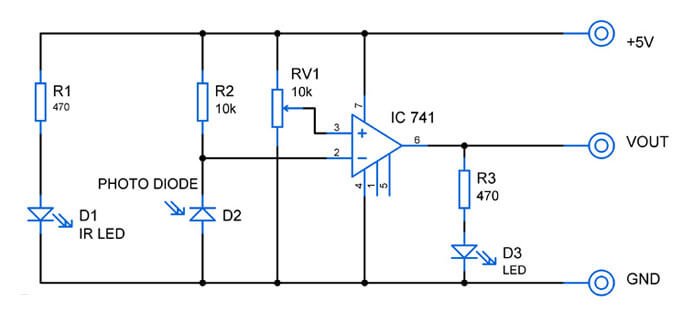

Here is how to build a simple infrared sensor circuit that can be used in any application that requires detection. Infrared sensor module circuit design:

Processing:

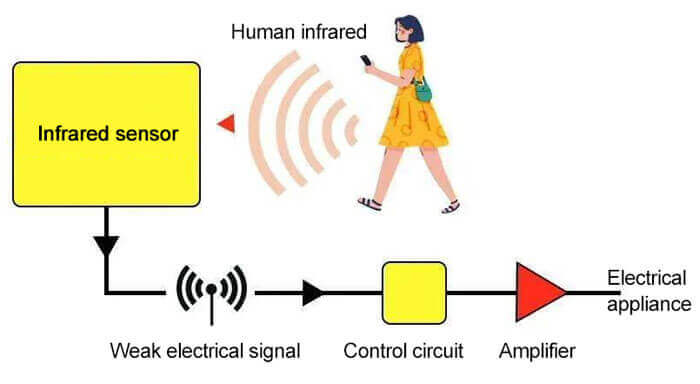

A simple infrared LED and photodiode are used to emit and sense the infrared beam. The operational amplifier IC 741 is used as a comparator to switch the output level to logic 1 or logic 0. The variable resistor RV1 is used to adjust the sensitivity of the detector by changing the reference voltage of the comparator. Finally, the LED D3 is used as an indicator when it is detected or reflected.

When the circuit is powered, the infrared LED D1 emits an infrared beam. The photodiode D2 is connected in series with the resistor R2 in a reverse biased manner. When there is no infrared beam incident in the photodiode, no current passes through it, which in turn causes the voltage to not drop and the inverting terminal of the operational amplifier is fed with a maximum voltage of 5V. Since the voltage at the inverting terminal is greater than the reference voltage at the “+” terminal of the operational amplifier, the output remains low or logic 0.

When the infrared beam is reflected by an object on the photodiode, current passes through it and in turn a voltage drop occurs between the terminals. Now, the reference voltage at the “+” terminal of the operational amplifier is greater than the “-” terminal. The output of the operational amplifier switches to high or logic 1 state.

This design is useful for interfacing with microcontrollers for detection as it provides two logic level outputs, compatible with many microcontrollers.

Application of infrared sensors

Automatic control

In the process of automated production, infrared sensors can be used to detect the position, speed and shape of objects to achieve precise control of the production process. For example, control the grabbing and placing actions of the robotic arm, detect the approach of pedestrians and automatically open the door.

Security monitoring

By detecting the infrared radiation emitted by the human body, infrared motion detectors can detect and alarm intruders. Widely used in anti-theft alarm systems in homes, offices, warehouses, laboratories, etc.

Smart home

By detecting the infrared radiation and motion information of people, infrared sensors can realize functions such as intelligent lighting and intelligent temperature control. For example, when a person enters a room, the infrared sensor can automatically turn on the lights and air conditioners.

Medical field

Infrared sensors can be used for contactless temperature measurement and disease diagnosis. For example, the thermal image of the surface temperature of a person is measured at a long distance, and the abnormal temperature is found to assist doctors in diagnosis. Infrared sensors can also be used to measure blood flow rate and monitor heart function.

Military and space technology

In the military, infrared sensors can be used for target tracking, missile guidance and satellite remote sensing. By detecting the infrared radiation emitted by the target and analyzing and processing it, the target can be tracked and located. Infrared sensors can monitor environmental data such as the earth’s clouds and ocean temperature.

Nondestructive testing

This is a method of testing the physical or chemical properties of an object without damaging it. Infrared sensors are also widely used in the field of nondestructive testing. Nondestructive testing is an indispensable technology in modern industry to ensure product quality and safety.