What is a water level sensor?

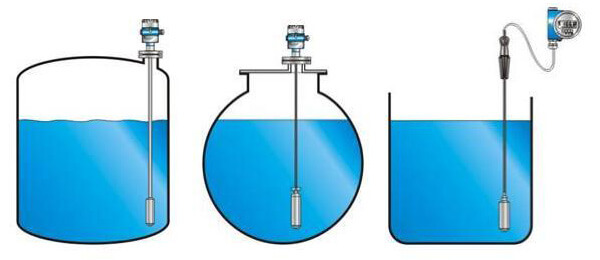

The water level sensor is a device that measures the liquid level in a fixed container that is too high or too low. According to the method of measuring the liquid level, it can be divided into two types: contact type and non-contact type. The input type water level transmitter we call is a contact measurement, which converts the height of the liquid level into an electrical signal for output. It is currently a widely used water level transmitter.

How does the water level sensor work?

The working principle of the water level sensor is that when it is put into a certain depth in the liquid to be measured, the pressure on the sensor’s front surface is converted into the liquid level height. The calculation formula is Ρ=ρ.g.H+Po, in the formula P is the pressure on the liquid surface of the sensor, ρ is the density of the liquid to be measured, g is the local acceleration of gravity, Po is the atmospheric pressure on the liquid surface, and H is the depth at which the sensor drops into the liquid.

The level sensor is a device designed to monitor and measure liquid (and sometimes solid) levels. When the liquid level is detected, the sensor converts the sensed data into an electrical signal. Level sensors are mainly used for monitoring reservoirs, oil tanks or rivers.

Where to use water level sensors?

The uses of water level sensors include the following applications:

- Water level measurement of pools and water tanks.

- Water level measurement of rivers and lakes.

- Marine level measurement.

- Level measurement of acid-base liquids.

- Oil level measurement of oil trucks and mailboxes.

- Swimming pool water level control.

- Tsunami warning and sea-level monitoring.

- Cooling tower water level control.

- Sewage pump level control.

- Remote monitoring of the liquid level.

What are the benefits of water level sensors?

- Simple structure: There are no movable or elastic elements, so the reliability is extremely high, and there is no need for regular maintenance during use. The operation is simple and convenient.

- Convenient installation: When using, first connect one end of the wire correctly, and then put the other end of the water level probe into the solution to be measured.

- Ranges are optional: you can measure the water level in the range of 1-200 meters, and other measurement ranges can also be customized.

- Wide range of applications: suitable for liquid level measurement of high temperature and high pressure, strong corrosion, high pollution, and other media. Building an electronic water level gauge on the river bank can be used for tide monitoring.

- Wide range of measuring medium: High-precision measurement can be carried out from the water, oil to paste with high viscosity, and wide-range temperature compensation is not affected by the foaming, deposition, and electrical characteristics of the measured medium.

- Long service life: Generally, the liquid level sensor can be used for 4-5 years in a normal environment, and it can also be used for 2-3 years in a harsh environment.

- Strong function: It can be directly connected to the digital display meter to display the value in real-time, or it can be connected to a variety of controllers and set the upper and lower limits to control the water volume in the container.

- Accurate measurement: The built-in high-quality sensor has high sensitivity, fast response, and accurately reflects the subtle changes of the flowing or static liquid level, and the measurement accuracy is high.

- Variety of types: liquid level sensors have various structural designs such as input type, straight rod type, flange type, thread type, inductive type, screw-in type, and float type. It can meet the measurement needs of all different places.

What are the types of water level sensors?

Here are 7 types of liquid level sensors for your reference:

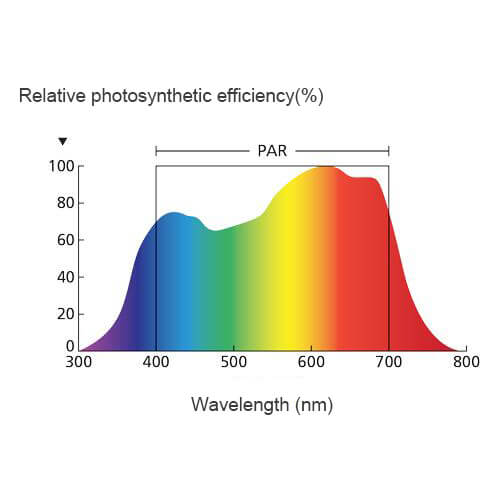

The optical sensor is solid-state. They use infrared LEDs and phototransistors, and when the sensor is in the air, they are optically coupled. When the sensor head is immersed in the liquid, the infrared light will escape, causing the output to change. These sensors can detect the presence or absence of almost any liquid. They are not sensitive to ambient light, are not affected by foam when in air, and are not affected by small bubbles when in liquid. This makes them useful in situations where state changes must be recorded quickly and reliably, and in situations where they can operate reliably for long periods without maintenance.

Advantages: non-contact measurement, high accuracy, and fast response.

Disadvantages: Do not use under direct sunlight, water vapor will affect the measurement accuracy.

2. Capacitance liquid level sensor

Capacitance level switches use 2 conductive electrodes (usually made of metal) in the circuit, and the distance between them is very short. When the electrode is immersed in the liquid, it completes the circuit.

Advantages: can be used to determine the rise or fall of the liquid in the container. By making the electrode and the container the same height, the capacitance between the electrodes can be measured. No capacitance means no liquid. A full capacitance represents a complete container. The measured values of “empty” and “full” must be recorded, and then 0% and 100% calibrated meters are used to display the liquid level.

Disadvantages: The corrosion of the electrode will change the capacitance of the electrode, and it needs to be cleaned or recalibrated.

3. Tuning fork level sensor

The tuning fork level gauge is a liquid point level switch tool designed by the tuning fork principle. The working principle of the switch is to cause its vibration through the resonance of the piezoelectric crystal.

Every object has its resonant frequency. The resonant frequency of the object is related to the size, mass, shape, force… of the object. A typical example of the resonant frequency of the object is: the same glass cup in a row Filling with water of different heights, you can perform instrumental music performance by tapping.

Advantages: It can be truly unaffected by flow, bubbles, liquid types, etc., and no calibration is required.

Disadvantages: Cannot be used in viscous media.

4. Diaphragm liquid level sensor

The diaphragm or pneumatic level switch relies on air pressure to push the diaphragm, which engages with a micro switch inside the main body of the device. As the liquid level increases, the internal pressure in the detection tube will increase until the microswitch is activated. As the liquid level drops, the air pressure also drops, and the switch opens.

Advantages: There is no need for power in the tank, it can be used with many types of liquids, and the switch will not come into contact with liquids.

Disadvantages: Since it is a mechanical device, it will need maintenance over time.

5. Float water level sensor

The float switch is the original level sensor. They are mechanical equipment. The hollow float is connected to the arm. As the float rises and falls in the liquid, the arm will be pushed up and down. The arm can be connected to a magnetic or mechanical switch to determine on/off, or it can be connected to a level gauge that changes from full to empty when the liquid level drops.

The use of float switches for pumps is an economical and effective method to measure the water level in the pumping pit of the basement.

Advantages: The float switch can measure any type of liquid and can be designed to operate without any power supply.

Disadvantages: They are larger than other types of switches, and because they are mechanical, they must be used more frequently than other level switches.

6. Ultrasonic liquid level sensor

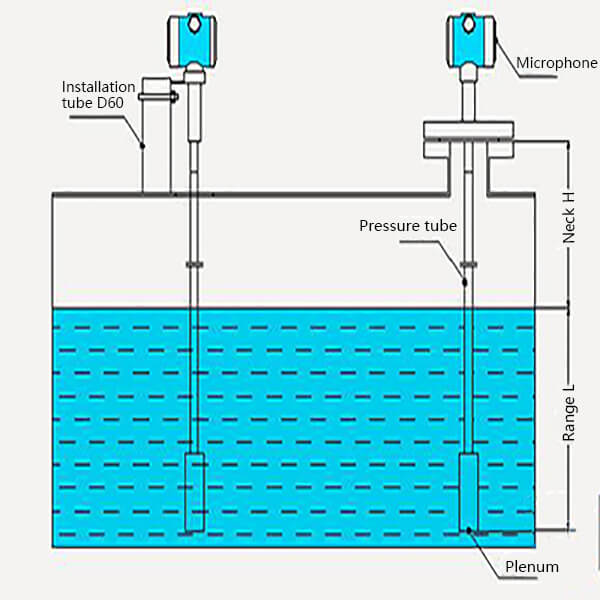

The ultrasonic level gauge is a digital level gauge controlled by a microprocessor. In the measurement, the ultrasonic pulse is emitted by the sensor (transducer). The sound wave is reflected by the liquid surface and received by the same sensor. It is converted into an electrical signal by a piezoelectric crystal. The time between the transmission and reception of the sound wave is used to calculate the Measure of the distance to the surface of the liquid.

The working principle of the ultrasonic water level sensor is that the ultrasonic transducer (probe) sends out a high-frequency pulse sound wave when it encounters the surface of the measured level (material), is reflected, and the reflected echo is received by the transducer and converted into an electrical signal. The propagation time of the sound wave. It is proportional to the distance from the sound wave to the surface of the object. The relationship between the sound wave transmission distance S and the sound speed C and the sound transmission time T can be expressed by the formula: S=C×T/2.

Advantages: non-contact measurement, the measured medium is almost unlimited, and it can be widely used for measuring the height of various liquids and solid materials.

Disadvantages: The measurement accuracy is greatly affected by the temperature and dust of the current environment.

A radar liquid level sensor is a non-contact liquid level measurement device based on the principle of electromagnetic wave reflection. It emits high-frequency electromagnetic waves toward the liquid surface and receives the echo signal, calculating the liquid level height using the time difference or frequency difference. Its core technology relies on the propagation characteristics of microwave signals, enabling it to adapt to complex working conditions such as high temperature, high pressure, corrosive environments, and steam. It is widely used in industries such as petrochemicals, energy storage and transportation, food, and pharmaceuticals.

Advantages: wide application range, not affected by temperature, dust, steam, etc.

Disadvantages: It is easy to produce interference echo, which affects the measurement accuracy.

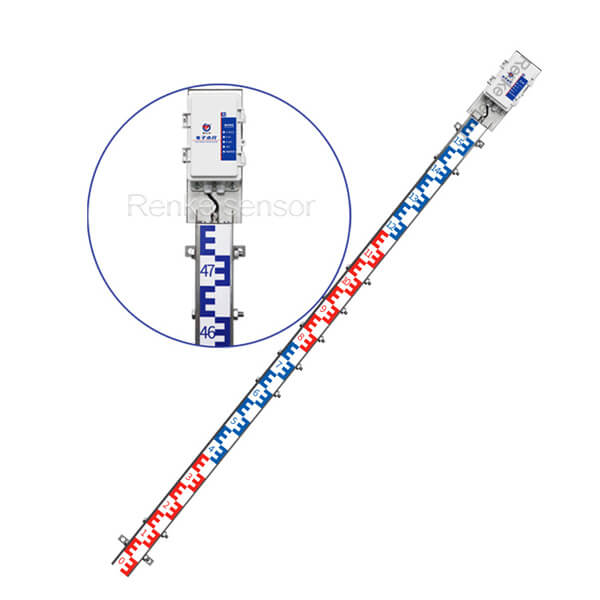

Renke water level measurements

In liquid level measurement, accuracy and reliability are crucial, especially in industries that require real-time monitoring under complex conditions. With the advancement of sensing technology, modern liquid level sensors have evolved to offer more stable and precise measurements. Among the widely used technologies, radar, ultrasonic, and hydrostatic pressure sensors stand out for their adaptability to different environments. Renke, as a professional environmental monitoring equipment manufacturer, provides a diverse range of liquid level sensors designed to meet various industrial and environmental monitoring needs. By considering factors such as medium characteristics, installation conditions, and measurement requirements, selecting the right sensor ensures efficiency and long-term stability in liquid level monitoring. Below are popular water level sensors from Renke: