Everyone knows that the choice of water quality sensors is very important. In water measurement, the ph sensor is one of the important tools. However, there are many kinds of ph sensors on the market, which makes many consumers wonder “how do I choose the right ph sensor?”, “Where do I start?”. This requires us to know the ph sensor information before using or buying, and then choose the appropriate sensor. In this article, we provide you with the types and applications of pH sensors suitable for different places.

What is ph sensor?

The ph sensor is a sensor used to detect the concentration of hydrogen ions in a solution and convert it into a corresponding usable output signal. It is usually composed of a chemical part and a signal transmission part. The measurement range is 0-14 digital representation. The value 7 indicates neutrality. The larger the value, the stronger the alkalinity; the smaller the value, the stronger the acidity. The ph sensor is often used for industrial measurement of substances such as solutions and water.

Different types of pH sensor

According to different usage environments, there are many kinds of ph sensors on the market. The correct choice of ph sensors can make your project more effective. On the contrary, choosing the wrong pH sensor will not only lead to inaccurate measurement, but also damage the electrode, leading to an increase in project cost. Different application places, we introduce to you the following 6 most widely used ph sensor electrodes:

1. pH composite sensor

An electrode that combines a pH glass electrode and a reference electrode is called a pH composite sensor. If the outer shell is plastic, it is called a plastic-shell pH composite sensor. If the outer shell is glass, it is called a glass pH composite sensor. The biggest advantage of the composite sensor is that it combines two into one and is easy to use.

Detection range: 0-14PH

Application: industrial sewage, domestic sewage, agriculture, aquaculture and other scenarios in a non-corrosive weak acid and weak alkali environment.

Note: The pH composite sensor must be immersed in pH4 buffer containing KCl before use, so that it can act on the glass bulb and the liquid junction at the same time. Special attention should be paid here, because in the past, people used single pH glass electrodes to be soaked in deionized water or pH4 buffer solution. Later, when using pH composite electrodes, they still use this immersion method, even in some incorrect pH composites. This kind of erroneous guidance will also be given in the electrode manual. The direct consequence of this wrong immersion method is to turn a pH composite electrode with good performance into an electrode with slow response and poor accuracy, and the longer the immersion time, the worse the performance. The KCl concentration inside the boundary has been greatly reduced, making the liquid junction potential increase and unstable. Of course, as long as the electrode is re-soaked in the correct soaking solution for a few hours, the electrode will still recover.

2. Desulfurization pH sensor

Desulfurization pH sensor is used for pH measurement in flue gas desulfurization. The electrode adopts a gel electrode, which is maintenance-free. The electrode can maintain high precision even at high temperature or high pH values. This kind of slurry and desulfurization special PH electrode, because it is flat, it is not easy to scale and easy to clean. Therefore, it is the most suitable electrode for desulfurization. It adopts anti-fouling annular PTFE liquid junction, which is not easy to be blocked and can be tested online for a long time.

Detection range: 0-14PH

Application: used in various industrial wastewater, environmental protection water treatment, mineral suspension, PH measurement in flue gas desulfurization, etc.

Desulfurization pH sensor has outstanding application in wet flue gas desulfurization process, and it adopts solid-state liquid junction design. All kinds of problems caused by the exchange and blockage of the liquid junction are completely avoided. For example, the reference electrode is easy to be polluted, reference vulcanization poisoning, reference loss and other problems. Secondly, the special wear-resistant pH bulb shows stable performance in the high-density and fast-flowing limestone slurry, which ensures the stable reaction rate of the pH electrode bulb and the accuracy of the signal.

Note: If the electrode sensitive membrane becomes dry, the electrode should be immersed in a neutral standard solution. It is recommended to soak in a 3M KCL solution for 24 hours. During the transportation and storage of the electrode, a small amount of KCL will overflow the electrode protective cap and form white crystals, which can be washed directly with water. Keep the sensitive membrane moist at all times, store the electrode in the electrode protective cap with 3M KCL solution, and prohibit the use of deionized water, distilled water, pure water, etc. to store the electrode.

3. PTFE pH sensor

The PTFE PH sensor is made of polytetrafluoroethylene, which is resistant to strong acids and alkalis, and is resistant to corrosion. It is suitable for monitoring the pH value in occasions containing organic substances. It uses a low-impedance glass sensitive film, which is wear-resistant, resistant to strong acids and alkalis. The probe is front-facing The ring-mounted protection ring protects the glass bulb with better accuracy and linearity.

Detection range: 0-14PH

Application: Widely used in industrial wastewater, acid-base neutralization, strong acid and strong base conditions, and severely polluted water.

Note: 1. Before measuring, wash it in distilled water or deionized water, and absorb the water with filter paper to prevent impurities from being brought into the measured solution. The electrode bulb and the liquid junction should be immersed in the measured liquid at the same time.

2. Wash the electrode when not in use, and put it in a protective cover with saturated potassium chloride solution, or put the electrode in a container with saturated potassium chloride solution (a bottle of electrode protection solution is distributed).

3. Check whether the terminal is dry, if it is polluted, wipe it with absolute alcohol and blow it dry before use.

4. Avoid long-term immersion in distilled water or protein solution, and prevent contact with silicone grease.

5. For the electrode that has been used for a long time, its glass film may become translucent or attached with deposits. In this case, it can be washed with dilute hydrochloric acid and rinsed with water.

6. It is recommended to clean the electrodes regularly-one time and coordinate with the instrument to calibrate.

4. Electroplating pH sensor

The double liquid junction is adopted to reduce the pollution of the reference liquid. The long-distance reference diffusion path greatly prolongs the service life of the electrode in harsh environments and is convenient for maintenance.

Detection range: 0-14PH

Application: Sewage treatment, electroplating wastewater fermentation, occasions with high organic content, etc.

5. pH Glass sensor

The pH value of the solution measured by the pH glass electrode is the saturated calomel electrode as the reference electrode, the glass electrode as the indicator electrode, and the measured water sample to form a working battery, and then use a PH meter to measure the working electromotive force, and the PH meter directly reads the pH. value. The pH glass electrode measures PH accurately and quickly, and is less interfered by factors such as water chromaticity, turbidity, colloidal substances, oxidants, reducing agents and salinity.

Detection range: 0-14PH

Application: Biological engineering, pharmacy, beer, chemical industry, semiconductor electronics industry or places with certain corrosive effects.

Note: 1. The accuracy of the measurement result is first determined by the accuracy of the pH standard value of the standard buffer solution.

2. The glass electrode and gangong electrode should be selected, processed and installed according to the specifications.

3. The pH value of the water sample should be measured on site, otherwise, the sample should be kept at 0-4℃ after sampling, and the measurement should be carried out within 6 hours after sampling. Pure water is neutral, and its pH value is 7.0 at 25 degrees. The solution below this value is acidic, and the value above this value is alkaline. Pure water also ionizes (a decomposition process that decomposes charged ions) to produce hydrogen ions.

6. PH antimony sensor

The PH antimony electrode is a redox electrode. When the surface of the metal antimony is in contact with the test solution, the surface is oxidized to form Sb2O3. The potential difference between the metal antimony and the oxide depends on the concentration of Sb2O3, and the concentration of Sb2O3 is consistent with that in the solution. The hydrogen ion concentration is related to, therefore, the pH value of the solution can be measured by measuring the potential difference between antimony and antimony trioxide. Antimony electrode is a pH-sensitive electrode. Because it is relatively strong, it is most suitable for the occasions where the electrode is required to be strong, but it has great limitations. Any component that has a substitution effect with antimony or generates complexes and ions cannot be used directly. . Antimony electrode is suitable for PH test of solution containing hydrofluoric acid.

Detection range: 0-14PH

Application: Online monitoring of breeding, sewage, hydrofluoric acid, etc.

Note: To be able to continuously measure the pH value of the solution, the dirt and oxides on the surface of the metal antimony electrode in contact with the measured solution should be cleaned at any time to keep the fresh surface of the metal antimony electrode to meet the requirements of the pure antimony surface and the measured solution Contact, thereby forming a new thin surface of Sb2O3, and so on again and again to maintain the accuracy and reliability of the pH measurement of the solution.

How to maintain the pH sensor?

If you want the pH sensor to keep in good condition, you must maintain the pH electrode regularly. Without proper maintenance, some common problems that may affect the electrode include: oily coating on the electrode, blockage or fouling of the reference contact, malfunction or breakage of the PH bulb, and short electrode life due to reference poisoning.

If the electrodes are usually coated with oil and other substances, consider using a sensor that includes a non-porous reference junction. The use of automated systems for cleaning electrodes can further reduce your maintenance needs. If the reference junction is often clogged or fouled, a non-porous electrode can also be used as a solution to this problem. If your pH bulb breaks when it comes in contact with sewage, you can use a bulb guard to protect it. As for the problem of reference poisoning, the use of non-porous electrodes can avoid these problems.

How to clean the pH sensor?

It only takes a few simple steps to clean your electrode to properly maintain and clean the pH electrode. Whenever handling pH electrodes, it is important to wear safety glasses and gloves. When the electrodes are not in use, they should always be kept in a liquid solution. If the electrode dries out, it can no longer be used. Most electrodes can only be purchased in saline solution, and you can continue to use them in the future.

In order to clean the electrode, you should put it in a solution consisting of 95% water and 5% hydrochloric acid. When the electrode is placed in this solution, most of the coating will dissolve. The sensor should be soaked for 5-10 minutes and then rinsed off. If the coating around the sensor is particularly heavy, the above steps should be repeated several times. Be sure to wipe the sensor with a soft cloth, as any abrasive cloth or brush will damage the electrode.

Why are different types of pH sensors important?

With modern water pollution becoming more and more serious today, it is urgent to protect the environment and protect water resources. Countries all over the world are paying attention to this issue. In some countries, industry is the backbone of the national economy. They know that it is not good to exchange economic development at the cost of the environment, but they have to do so. Therefore, water pollution is already a headache for the whole world. Sewage treatment equipment was developed under this background. Sewage treatment equipment can effectively treat domestic sewage and industrial waste water in urban areas to prevent sewage and pollutants from directly flowing into waters. PH sensor is an important part of sewage treatment equipment.

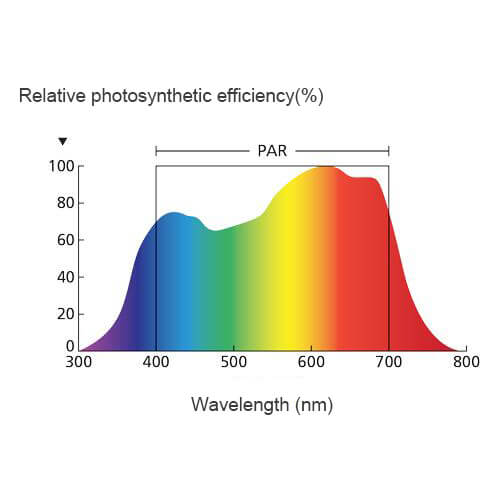

The pH value is one of the most commonly used water quality testing indicators, and the pH value of natural water is mostly in the range of 6-9. The pH value of drinking water should be between 6.5 and 8.5. The pH value of some industrial water should be guaranteed to be between 7.0 and 8.5, otherwise it will have a corrosive effect on metal equipment and pipelines. pH value and acidity, alkalinity are both different and connected. The pH value indicates the strength of the acidity and alkalinity of the water, and the acidity or alkalinity is the content of acid or alkali substances in the water. The change of pH in water quality indicates the degree of water pollution.

If the water pH is too high or too low, the aquatic organisms in it will die. PH value also affects the dissolved oxygen and toxicity of chemicals and heavy metals in the water. Most aquatic organisms like the pH range between 6.5 and 9.0, but some can live in water bodies with a pH beyond this range.

Therefore, whether it is industrial production, aquaculture, sewage treatment or agricultural production, a ph sensor is needed to detect the ph value in the liquid, which requires us to choose the appropriate ph sensor.