What is cold chain monitoring?

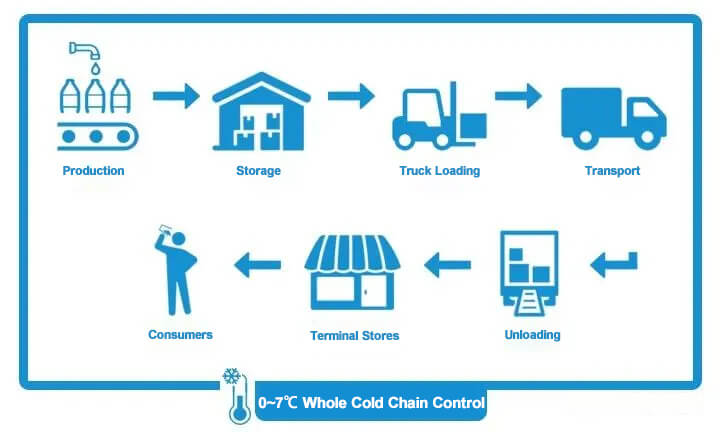

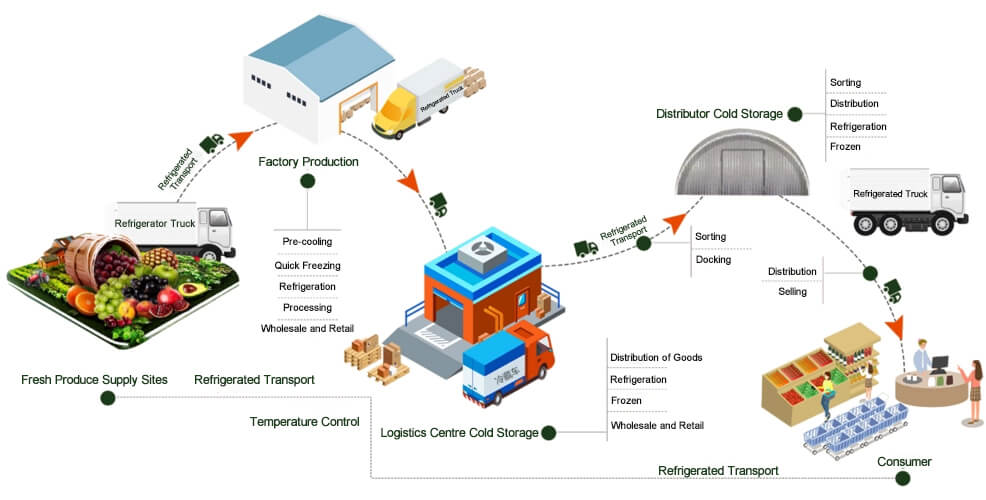

Cold chain monitoring is the real-time monitoring and control of temperature and humidity and other critical parameters during production, transportation and delivery to ensure the quality of products with stringent environmental requirements, such as food and pharmaceuticals. In order to ensure that products are always within safe temperature and humidity ranges, monitoring must be implemented at all stages of the supply chain. So the process of cold chain monitoring includes transportation, storage, distribution and packaging. Cold chain monitoring systems utilize a variety of sensors and IoT technologies to track and record the temperature of products during transportation.

Why is cold chain monitoring important?

Ensuring product quality

Maintaining the proper temperature of goods is critical during transportation and storage. Excessively high or low temperatures can lead to spoilage, damage or even failure of the goods. Cold chain monitoring systems monitor the temperature and humidity of goods in real time to ensure that they are always in the right environment. This precise temperature control and monitoring capability allows goods to remain fresh, safe and of high quality.

Improved logistics efficiency

While traditional cold chain logistics requires manual monitoring and recording of temperatures, modern cold chain monitoring systems can automate this process, reducing labor costs and the risk of errors. At the same time, logistics managers can monitor multiple transportation and storage segments in real time through the monitoring platform, improving visibility and coordination of operations. This automated monitoring greatly improves logistics efficiency.

Meeting consumer demand

As consumer demand for food safety and quality grows, so does cold chain monitoring technology. Supply chain managers are seeking more accurate and efficient monitoring equipment and techniques to meet consumer demands.

What technologies are used in cold chain monitoring?

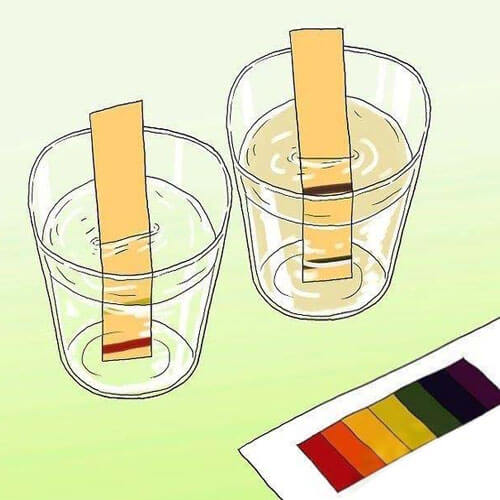

At present, cold chain temperature monitoring mainly adopts the following technologies:

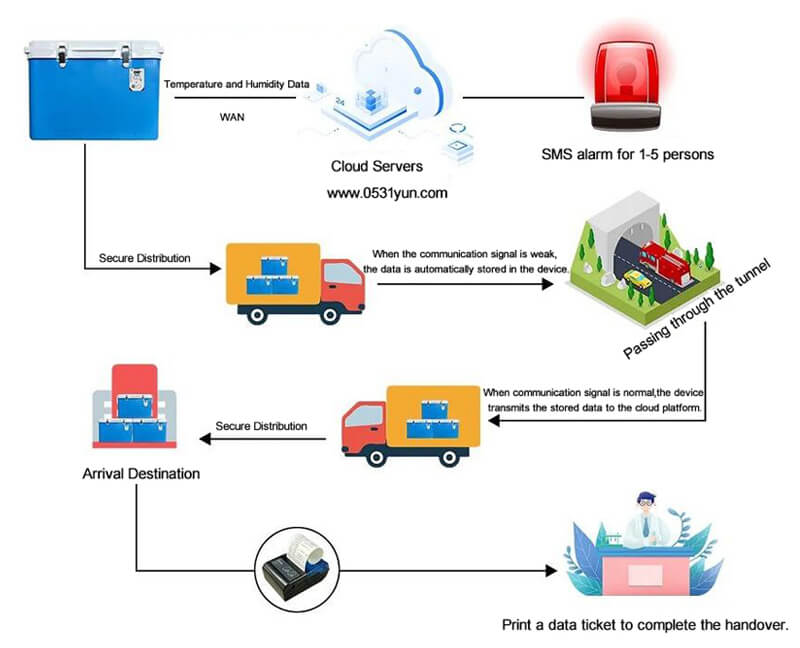

- Temperature data logger: temperature and humidity data logger is the core equipment for cold chain temperature monitoring, which can offer environment data of goods in real time, and store and transmit the data to the monitoring system.

- Data transmission technology: through wireless transmission technology, such as GPRS, LORA, etc., the temperature and humidity data can be transmitted to the monitoring center in real time to realize remote monitoring.

- Monitoring software: monitoring software can analyze and process the temperature and humidity data in real time, provide early warning, alarm and other functions, and help the management personnel to find out the abnormal situation in time.

Cold chain monitoring solutions

Cold chain equipment

1. Cooler box

Cooler box is the most basic equipment in cold chain transportation. It is used to store the goods and ensure a stable environment for the goods during the whole transportation process. Different kinds of products need different types of cooler boxs, such as vaccines need strict temperature control, so the cooler boxs should be equipped with embedded temperature and humidity data loggers to record the temperature in real time.

2.Temperature and humidity data logger

Temperature and humidity data logger is a tool used to record the temperature and humidity changes in the whole production and delivery process. Changes in temperature and humidity during transportation will affect the quality of the product, so the temperature and humidity recorder can help us grasp the value of temperature and humidity during the whole process and take timely measures to ensure that the quality of the goods is not affected.

3. Cloud platform and software applications

Cloud platforms and software applications are used to receive, store and analyze data uploaded by loggers. These platforms usually provide real-time alarms, data analysis and report generation to help supply chain managers monitor and manage effectively.

4. Other Equipment

Cold chain transportation also requires some other auxiliary equipment, such as packaging materials, anti-vibration supports, isolation boards, etc.. All these equipments are to ensure the safety of the products during the whole transportation process and keep them in low temperature.

Advantages of cold chain monitoring

Real-time monitoring and alarm

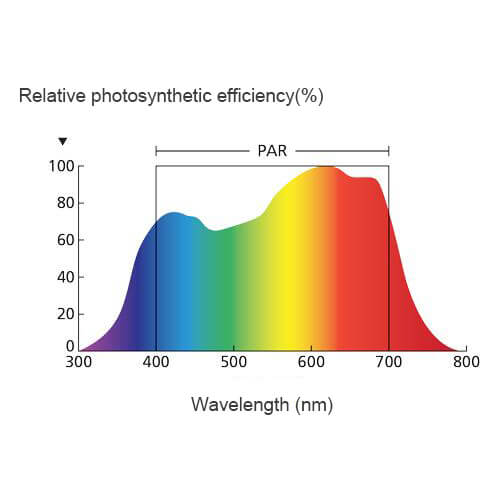

With the help of temperature and humidity data logger and internet technology, the cold chain monitoring system can monitor the temperature, humidity, air pressure and other key parameters inside the cold storage in real time and transmit the data to the cloud platform. Users and drivers can access the temperature changes inside the cold storage or refrigerator at anytime and anywhere through cell phones or computers. When the temperature or humidity exceeds the set upper and lower limits, the temperature and humidity data logger will also trigger an alarm function to remind the management to take timely measures to prevent the goods from being damaged or spoiled. This helps to improve logistics efficiency and reduce losses and disputes.

Early warning and data recording

The cold chain monitoring system also has an early warning function. Once the temperature in the compartment exceeds the preset range, the system will automatically send an alert message to the relevant personnel to ensure that the problem can be dealt with in time. In addition, the system is also able to record the equipment operation data, providing comprehensive historical data reports for the managers to realize the fine management of production.

Built-in storage

The data logger in the cold chain monitoring system has built-in storage function. In the tunnel where the signal disappears, the data can be stored temporarily, and after the communication is restored, the stored data will be automatically renewed. This makes the temperature and humidity data logger still be able to save the measurement data in case of power failure or communication failure, avoiding data loss and repeated measurement.

Device parameter configuration

On-site or remote management personnel can set or modify the parameters of the logger. There are buttons on the logger to manually set the upper and lower alarm limits. Remote managers can modify the parameters of the device through SMS configuration or control platform, simple and convenient.

Wireless transmission

The cold chain monitoring system adopts Loran, GPRS, 4G or other wireless transmission methods, which has no wiring problem and is not limited by distance. This allows the temperature and humidity logger to be easily accessed to remote cloud platforms, realizing real-time data sharing and remote monitoring.

Automatic control

The temperature and humidity data logger linkage control function supports start-stop control of air conditioners, fans, smart air conditioners and other equipment. Combined with the edge computing function of the system, constant temperature and humidity management of the environment can be realized.

Cold chain monitoring applications

Applications in the pharmaceutical industry

Pharmaceutical cold chain monitoring systems are responsible for ensuring temperature control and quality monitoring of pharmaceuticals throughout the transportation and storage process. It ensures that there is no loss of active ingredients in pharmaceutical products. Pharmaceutical cold chain monitoring system is responsible for monitoring the temperature, humidity and other key environmental indicators from the beginning of the production of pharmaceuticals out of the factory. The transportation of medicines is monitored in real time through sensors and data acquisition technology. This avoids the influence of ambient temperature fluctuations during transportation and maintains the stability and safety of pharmaceuticals.

Applications in the food industry

In the whole process from pre-cooling at origin, storage in automated cold storage, full cold chain transportation to end distribution, temperature and humidity should be monitored and managed in each process to ensure that the food is always under suitable temperature and humidity conditions. The cold chain monitoring system ensures that the right environment is maintained throughout the process by monitoring the status of refrigeration equipment and temperature and humidity data in real time, thus ensuring the quality and health of the food.