Table of Contents The Internet of Things (IoT) is one of the hottest technology words in the past few years, which can collect, share, analyze

Explosion-proof Pressure Sensor

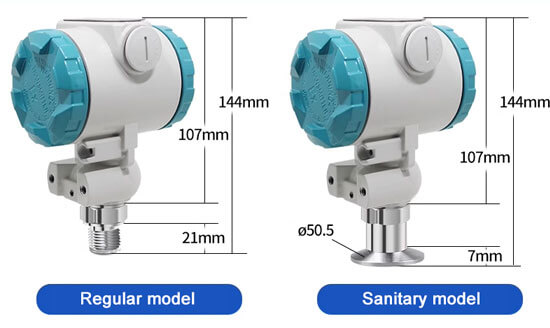

Our explosion-proof pressure sensor adopts laser resistance trimming temperature compensation process, which has higher measurement accuracy and more stability. It has reverse polarity protection and instantaneous overcurrent and overvoltage protection, and meets EMI protection requirements. It has reliable quality, small size and high cost performance. It can be equipped with LCD display for easy on-site data reading.

- Model: RK-PM400-EX

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price: $51.4~$110

View Explosion-proof Pressure Sensor

Our explosion-proof pressure sensor adopts a high-performance pressure-sensitive chip, combined with advanced circuit processing and temperature compensation technology, to convert pressure changes into linear current or voltage signals. Our company offers two output signal options: analog and RS485, which can be connected to on-site PLCs, configuration software, HMI screens, or industrial controllers. Additionally, our networked data concentrators or monitoring hosts can be used to upload data to our free cloud platform, allowing users to view real-time data, historical records, and alarm logs via a computer or mobile app.

Additionally, the sanitary (flush diaphragm) pressure sensor is based on this pressure sensor but features a welded, sealed isolation diaphragm. This diaphragm sealing device comes in various structural designs, making it particularly suitable for high-temperature, high-viscosity, and crystallized media, as well as environments prone to clogging. It is also ideal for pressure measurement in sanitary and pharmaceutical applications.

Parameters

| Output signal | RS485 | 4-20mA/0-5V/0-10V |

|---|---|---|

| Power supply | 10-30V DC | 12-36V DC |

| Measure range | -0.1~+100MPa (optional) | |

| Accuracy | 0.2%FS, 0.5%FS (default) | |

| Overload capacity | <1.5 times the range | |

| Temperature drift | ≤ ±1.5%FS | 0.03%FS/℃ |

| Medium temperature | -40~75℃; -40~150℃ (high temperature type) | |

| Measure medium | Gas and liquid that are non-corrosive to stainless steel | |

| Long-term stability | ≤ ±0.3%FS | — |

| Response time | ≤1ms | — |

| Protection level | IP65 | |

Features

- All stainless steel structure, protection level IP65

- Laser resistance adjustment temperature compensation process, higher measurement accuracy and more stable

- Reverse polarity protection and instantaneous overcurrent and overvoltage protection, in line with EMI protection requirements

- Pressure overvoltage protection, instantaneous overvoltage resistance of 1.5 times

- Vibration and shock resistance, anti-radio electromagnetic interference

- Automatic temperature compensation, automatic temperature drift correction

Applications

This explosion-proof pressure sensor is compact and easy to install, with an optional LCD display. Its housing is made of stainless steel, providing waterproof and corrosion-resistant properties, making it suitable for measuring gases or liquids that do not corrode stainless steel. It can measure gauge pressure, negative pressure, and absolute pressure, making it an ideal choice for industrial process pressure measurement. It is widely used in water plants, refineries, wastewater treatment plants, construction materials, light industry, and the machinery sector for measuring the pressure of liquids, gases, and steam.

Explosion-Proof Pressure Sensor Installation

When you receive the explosion-proof pressure sensor provided by our company, please carefully read the manual and check the packaging list.

During installation, check whether the on-site interface matches the sensor’s connection type and thread specifications. When connecting, tighten slowly and avoid applying torque directly to the sensor housing—apply torque only to the hexagonal section of the pressure interface. Ensure that the explosion-proof pressure sensor is installed vertically to the ground. Use a wrench to tighten it from the hexagonal nut at the base of the sensor, avoiding direct rotation of the upper part of the sensor. Choose an installation location that allows for easy operation and maintenance, and keep it as far away as possible from sources of vibration or heat.

When connecting the power supply, strictly follow the wiring instructions provided by our company.

Renke explosion-proof pressure sensor is a precision instrument. Do not disassemble it arbitrarily during transportation or installation. Additionally, avoid collisions, drops, or contact with sharp objects on the sensor diaphragm to prevent damage to the core component.

Ensure proper sealing of the external thread on the pressure sensor; otherwise, inaccurate or unstable pressure readings may occur.

Related Blogs

Table of Contents Did you know? Atmospheric pressure is constantly influencing the natural phenomena around us—everything from the direction of winds, to cloud formation, and

Table of Contents What is differential pressure? Differential pressure is the difference between the values of the pressures at different locations. For example, if the

Table of Contents What is a vibration sensor? Vibration sensor is a device that measure the vibration speed and frequency of mechanical motion and convert

Measuring tilt angles is an important part of geometric metrology. The range of angle measurement is wide. According to the spatial position of the plane,

Table of Contents Smart buildings are the product of the development of modern science. The smart building system is mainly composed of Internet of Things

The key to the smart industry lies in the collection of data and information. Sensors are the nerve endings of the smart industry. They are

Table of Contents What is IoT? IoT is the “Internet of things“. It is an extended and expanded network based on the Internet. It combines

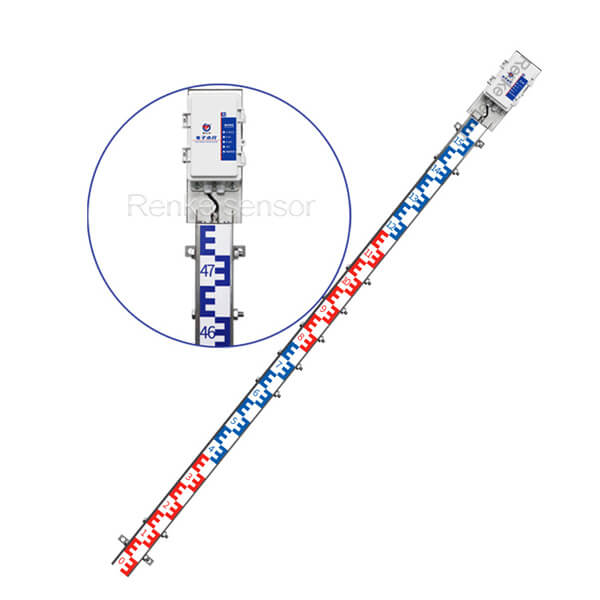

Table of Contents What is a water level sensor? The water level sensor is a device that measures the liquid level in a fixed container