What is a temperature probe?

A temperature probe is a sensor that senses temperature and converts it into a usable output signal. Temperature probes are the core part of temperature monitoring devices, which are widely used in various industries.

Some temperature probes can measure temperature by placing them on the surface of an object. Some temperature probes need to be inserted into the object (or immersed in liquid) to measure the temperature. The principle of this temperature sensor probe is energy conservation. When the temperature of the measuring probe is lower than the medium, the heat energy is transferred from the measured medium to the probe. When the probe temperature is higher than the medium, thermal energy is transferred from the probe to the medium.

The shape of the temperature probe is various, mainly because of the difference of the measurement place and the measurement method. Some need waterproofing, some need high temperature resistance, some need to measure deeply inside the object, and some need non-contact measurement.

Four types of temperature probes

According to the difference in measurement principle. The temperature probes can be roughly divided into four types: Negative Temperature Coefficient (NTC) temperature probes, Resistance Temperature Detector (RTD) temperature probes, Thermocouple temperature probes, and Semiconductor-Based temperature probes.

NTC temperature probes

An NTC temperature probe is a type that uses a thermistor. The principle is that the resistance value decreases rapidly as the temperature rises, which is usually composed of 2 or 3 metal oxides, mixed in a fluid-like clay, and calcined in a high-temperature furnace into a dense sintered ceramic. Actual size is very flexible, they can be as small as 0.010 inches or very small diameters. There is almost no limit to the maximum size, but generally less than half an inch applies.

| Pt100 thermal resistance resistance temperature comparison table | ||||||||||

| Temp ℃ | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Resistance value (Ω) | ||||||||||

| 0 | 100.00 | 100.40 | 100.79 | 101.19 | 101.59 | 101.98 | 102.38 | 102.78 | 103.17 | 103.57 |

| 10 | 103.96 | 104.36 | 104.75 | 105.15 | 105.54 | 105.94 | 106.33 | 106.73 | 107.12 | 107.52 |

| 20 | 107.91 | 108.31 | 108.73 | 109.10 | 109.49 | 109.88 | 110.28 | 110.67 | 111.07 | 111.46 |

| 30 | 111.85 | 112.25 | 112.64 | 113.03 | 113.43 | 113.82 | 114.21 | 114.60 | 115.00 | 115.39 |

| 40 | 115.78 | 116.17 | 116.57 | 116.96 | 117.35 | 117.74 | 118.13 | 118.52 | 118.91 | 119.31 |

| 50 | 119.70 | 120.09 | 120.48 | 120.87 | 121.26 | 121.65 | 122.04 | 122.43 | 122.82 | 123.21 |

| 60 | 123.60 | 123.99 | 124.38 | 124.77 | 125.16 | 125.55 | 125.94 | 126.33 | 126.72 | 127.10 |

| 70 | 127.49 | 127.88 | 128.27 | 128.66 | 129.05 | 129.44 | 129.82 | 130.21 | 130.60 | 130.99 |

| 80 | 131.37 | 131.76 | 132.15 | 132.54 | 132.92 | 133.31 | 133.70 | 134.08 | 134.47 | 134.86 |

| 90 | 135.24 | 135.63 | 136.02 | 136.40 | 136.79 | 137.17 | 137.56 | 137.94 | 138.33 | 138.72 |

| 100 | 139.10 | 139.49 | 139.87 | 140.26 | 140.64 | 141.02 | 141.41 | 141.79 | 142.18 | 142.56 |

| 110 | 142.96 | 143.33 | 143.71 | 144.16 | 144.48 | 144.86 | 145.25 | 145.63 | 146.20 | 146.40 |

| 120 | 146.78 | 147.16 | 147.55 | 147.93 | 148.31 | 148.69 | 149.07 | 149.46 | 149.84 | 150.22 |

| 130 | 150.60 | 150.98 | 151.37 | 151.75 | 152.13 | 152.51 | 152.89 | 153.27 | 153.65 | 154.03 |

| 140 | 154.41 | 154.79 | 155.17 | 155.55 | 155.93 | 156.31 | 156.69 | 157.07 | 157.45 | 157.83 |

| 150 | 158.21 | 158.59 | 158.97 | 159.35 | 159.73 | 160.11 | 160.49 | 160.86 | 161.24 | 161.63 |

| 160 | 162.00 | 162.38 | 162.76 | 163.13 | 163.51 | 163.89 | 164.27 | 164.64 | 165.02 | 165.40 |

| 170 | 165.78 | 166.15 | 166.53 | 166.91 | 167.28 | 167.66 | 168.03 | 168.41 | 168.79 | 169.10 |

| 180 | 169.54 | 169.91 | 170.29 | 170.67 | 171.04 | 171.42 | 171.79 | 172.17 | 172.54 | 172.92 |

| 190 | 173.29 | 173.67 | 174.04 | 174.41 | 174.79 | 175.16 | 175.54 | 175.91 | 176.28 | 176.66 |

| 200 | 177.03 | 177.40 | 177.78 | 178.15 | 178.52 | 178.90 | 179.27 | 179.64 | 180.02 | 180.39 |

RTD temperature probes

“RTD” is an abbreviation for “Resistance Temperature Detector”. Typically, RTDs contain platinum, nickel, or copper wire because these materials are positive temperature coefficient materials. This means that resistance increases as temperature increases, and this change in resistance will be used to detect and measure temperature changes.

Most RTD probes are configured in one of three ways: wire-wound RTD, coil element RTD, and thin-film RTD.

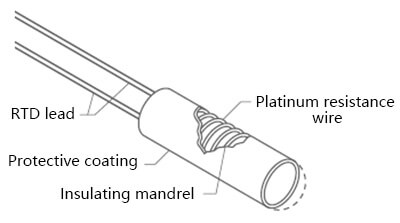

Wire-wound RTD

In a wire-wound RTD, the resistance wire is wound on an insulating mandrel made of ceramic. Sensor manufacturers carefully trim the length of the resistance wire to achieve the specified resistance value at 0°C. This is called the “R0” resistor.

Next, connect the wires to the resistive wire, then coat the wires with glass or ceramic for protection. As the temperature increases, the length of the resistance wire increases slightly. Design must ensure that the resistance wire does not twist or deform as the temperature rises. Because the mechanical strain will cause the wire resistance to change.

Laboratory-grade RTDs used in calibration laboratories eliminate this error by wrapping the resistance wire loosely around an insulating post. This type of RTD is very accurate but very fragile and not suitable for most industrial applications.

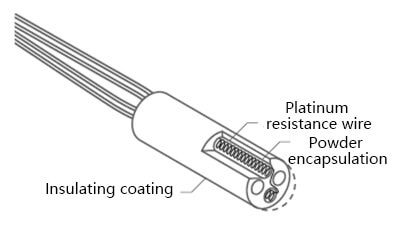

Coil element RTD

In a coil element RTD, the resistance wire is rolled into small coils, loosely packed into a ceramic tube, which is then filled with insulating powder. The resistance wire expands and contracts freely with temperature changes, minimizing errors caused by a mechanical strain.

The powder increases the rate of heat transfer into the coil, which improves response time. Coil element RTDs are usually protected by a metal jacket and are suitable for industrial applications.

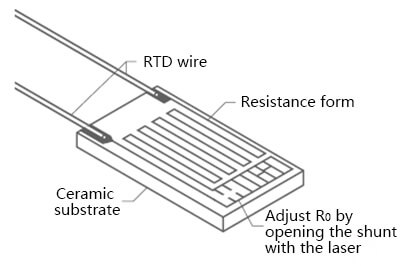

Thin-film RTD

Thin-film RTDs can be mass produced and cost less than other types of RTDs. Thin-film RTDs are smaller and respond faster than other types of RTDs, a desired effect for many applications. Thin-film RTDs are fabricated by depositing a thin layer of platinum on a ceramic substrate to form pathways.

Thermocouple temperature probes

The principle of thermocouple temperature probe is: when two different metals are connected, one end is placed in a low temperature, and the other end is placed in the same high temperature, a potential difference will be generated. Such a pair of metals is called a thermocouple. Because this temperature difference is almost proportional to the potential difference and has a very good linear relationship, it can be used to find the temperature by measuring the voltage. Thermocouple temperature probes have a very wide measurement range from -200 °C to 1750 °C. Of course, it’s also less accurate.

Semiconductor-Based temperature probes

Semiconductor-based temperature probes are often shrunk into integrated circuits (ICs). These sensors use two identical diodes with temperature-sensitive voltage and current characteristics to monitor changes in temperature. They provide linear response but are the least accurate of the basic sensor types. These temperature sensors also have the slowest response over the narrowest temperature range (-70 °C to 150 °C).

Application of temperature probes

1. Temperature probes used in industry

Industrial metallurgy and smelting, petrochemical, thermal power and nuclear power, machinery manufacturing, brewing, pharmaceutical, water treatment, and other industries all need temperature detection, and temperature probes can easily achieve long-term temperature monitoring.

2. Temperature probes used in the medical industry

The application of temperature probes in medical electronics is common. For example, non-contact thermometers can measure heat emitted from a remote infrared radiant heat source, thermistor element temperature sensors used in blood analyzers, used to monitor the temperature of compartments, diffusion lamps and oil-cooled motors to avoid overheating, In case of overheating, immediately stop the machine to cool it down.

3. Temperature probes used in the food industry

Temperature probes also play an important role in the food processing industry. In the processing process of the food factory, when workers fry the condiments, they need to mix the raw materials at different times and at different temperatures, and then stir fry, and the temperature of the frying pan should be controlled during the frying process. Therefore, using a temperature probe for temperature detection has an important impact on whether the temperature of the frying pan in the workshop is accurate and the quality of the seasoning.

Conclusion

Thermocouples, RTDs, thermistors, and semiconductor-based ICs are the main types of temperature sensor probes in use today. Thermocouple probes have a wide measurement range and are rugged, but they have low accuracy and poor noise immunity. RTD probes have a wider temperature measurement range (although smaller than thermocouples), they have high accuracy and good linearity, but they are slower in response and more expensive. Thermistor probes are durable and small, but they are not as accurate as RTDs and require more data correction to account for temperature. Semiconductor-based ICs can be implanted flexibly and in extremely small packages, but they have a limited temperature range.

There are many types of temperature probes on the market. This blog mainly introduces these four types. If you want to buy or have questions about temperature probes, please leave us a message.