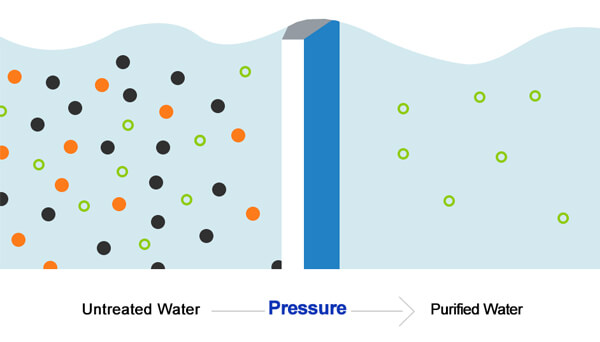

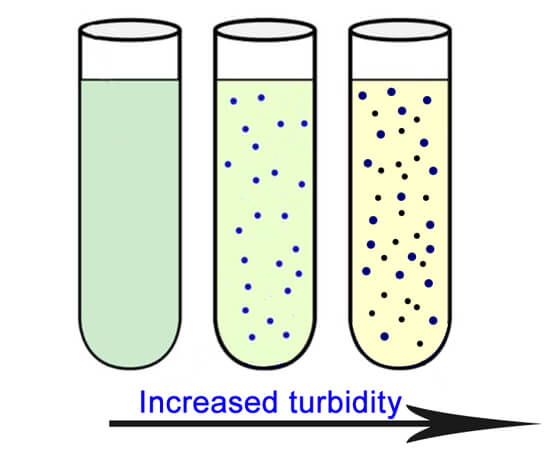

We need to understand what is turbidity, before learning the turbidity sensor. Turbidity is a measure of water quality that reflects the amount of suspended particles in a water sample by observing the amount of light scattered through it. The more pronounced the light scattering, the higher the turbidity of the water. Typically, the factors that affect water turbidity are the content of suspended solids and tiny particles. These tiny particles can be composed of sediment, clay, organic and inorganic materials, dissolved organic compounds, and algae. Water with high turbidity often requires purification processes before it can be used in industrial and domestic applications. This is because a decrease in turbidity often implies a reduction in harmful substances, bacteria, and viruses in the water.

Why need to measure water turbidity?

Turbidity in Drinking Water

The higher the turbidity in drinking water, the greater the risk of gastrointestinal diseases in humans. This is because contaminants such as viruses and bacteria can attach themselves to suspended solids. These solids can interfere with disinfection processes. Drinking water is typically treated surface water or groundwater because the particles and microorganisms naturally present in surface water and groundwater are not suitable for direct human consumption. Currently, drinking water regulations stipulate that turbidity should not exceed 1 NTU (Nephelometric Turbidity Unit).

According to the World Health Organization, drinking water is available for people to use when the turbidity is below 1 NTU. If the turbidity is above 1 NTU, it must continue to be treated before workers can use it. Therefore, the drinking water treatment system needs to install a turbidity sensor to monitor whether the water quality reaches the standard. Not only that, once the turbidity of the treated water does not meet the standard, the staff can be reminded to promptly check whether the equipment and pipelines of the water treatment system are faulty.

Turbidity in Industrial Water

Monitoring turbidity in industrial water is also essential because high turbidity levels can damage equipment and reduce its lifespan. For instance, water with high turbidity can increase frictional resistance in equipment such as water pumps and pipelines, leading to higher energy consumption. Impurities in the water can cause abrasion on equipment, especially in terms of transmission machinery and agitators. Prolonged abrasion can significantly decrease the equipment’s operational lifespan.

High turbidity in industrial water often indicates the presence of a significant amount of algae, bacteria, and other microorganisms. These organisms can grow on the inner walls of pipelines, causing blockages. Practical experience has shown that in industrial cooling water systems with side-stream filtration, supplementary water turbidity can be controlled to within 5 NTU.

Turbidity in Rivers and Reservoirs

Excessive turbidity in rivers, lakes and reservoirs affects the amount of light reaching the depths of the water body. Reduced light can inhibit the growth of some aquatic plants and negatively impact species such as fish and shellfish that rely on algae as a food source. High turbidity also hinders fish’s ability to absorb dissolved oxygen. This phenomenon has been observed and documented throughout the Chesapeake Bay in the mid-Atlantic region of the United States.

This video from @NEIWPCC

What is a turbidity sensor?

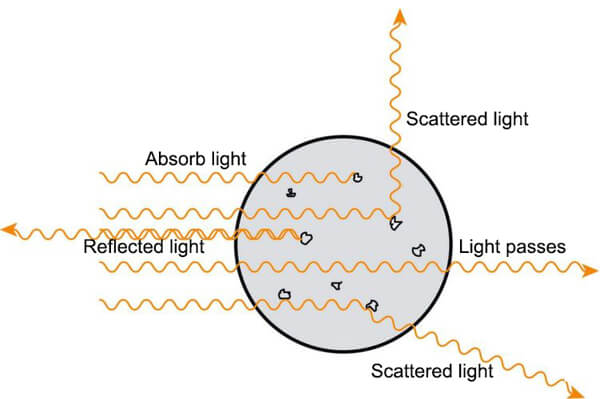

The turbidity sensor is a device measure the concentration of suspended particles in a solution use light scattering. When light passes through a solution, suspended particles in the water can absorb the light or reflect it. When light is reflected, its angle and intensity also change. Based on these changes, the turbidity of the liquid is calculated.

How does a turbidity sensor work?

The working principle of a turbidity sensor involves measuring the intensity of the interaction between light and suspended particles in a liquid sample. The interaction between light and suspended particles affects in two main ways: scattering and absorption.

Scattering: Particles in the liquid scatter light. Because the size and shape of the particles in the liquid are different, the angle and intensity at which the light is scattered are also different. Some of the scattered light can be directed to the detector.

Absorption: Certain particles in a liquid may absorb certain wavelengths of light. Different types of particles absorb light in different wavelength ranges, and to varying degrees. So the intensity of light decreases as it passes through a solution.

Turbidity unit

When measuring turbidity, you will usually see the units NTU, JTU or FTU. The conversion relationship between them is:

| Unit | JTU (degrees) | FTU (NTU) | SiO2(mg/l) |

| JTU (degrees) | 1 | 19 | 2.5 |

| FTU (NTU) | 0.053 | 1 | 0.13 |

| SiO2(mg/l) | 0.4 | 7.5 | 1 |

- JTU is the unit of turbidity measured with diatomite or kaolin as the turbidity standard solution and measured by the Jackson candle turbidimeter.

- NTU is the unit of turbidity measured with methyl wax as the turbidity standard solution and measured with a scattered light nephelometer.

- FTU is the unit of turbidity measured by a transmitted light nephelometer.

Three types of turbidity sensor

1. Absorption Turbidity Sensors

An absorption turbidity sensor is a device used to measure the turbidity of a liquid by evaluating the extent to which the liquid sample absorbs light. Its light source typically consists of an LED (Light Emitting Diode) that emits light at a specific wavelength or within a certain wavelength range. The emitted light passes through the liquid sample being tested. When the light encounters suspended particles or molecules in the liquid, some of the light is absorbed by these particles. The remaining transmitted light is measured by a photodetector. The sensor then converts the detected light intensity into a turbidity measurement value. This is usually done by comparing the intensity of transmitted light with the intensity of incident light (the light before it passes through the sample).

Commonly used units for turbidity are NTU (Nephelometric Turbidity Unit) or FTU (Formazine Turbidity Unit), depending on the measuring principle and standard of the sensor.

Absorption turbidity sensors are widely used in environmental monitoring, food and beverage, water treatment, industrial production and laboratories to control the turbidity of liquids in various processes.

2. Nephelometric Turbidity Sensors

A nephelometric turbidity sensor is a device used to measure the turbidity or cloudiness of a liquid sample by evaluating the light scattering caused by suspended particles in the liquid.

The light source of a turbidity sensor is typically an LED (Light Emitting Diode), and the emitted light is directed into the liquid sample being tested. As the light passes through the sample, it encounters suspended particles or molecules. These particles scatter the incident light in various directions. The sensor includes photodetectors or photodiodes placed at specific angles to detect the scattered light. It measures the intensity of the scattered light at a specific angle relative to the incident light. The amount of scattered light is directly related to the concentration and size of suspended particles in the liquid.

Turbidity measurement results are usually expressed in units such as NTU (Nephelometric Turbidity Units) or FNU (Formazin Nephelometric Units), depending on the calibration and standards used by the sensor.

Nephelometric turbidity sensors are used to measure the turbidity of drinking water, pharmaceuticals, or other types of low-turbidity water samples.

3. Suspended Solid Turbidity Sensors

A Total solid/suspended solid turbidity sensor is a device used to measure the concentration of total suspended solids in a liquid sample. Total suspended solids refer to the mass of solid particles suspended in a liquid, typically measured in milligrams per liter (mg/L) or parts per million (ppm).

An LED emits light at a specific wavelength into a liquid sample containing suspended solids. As the light passes through the sample, it interacts with the suspended particles. Detectors are used to measure the intensity of scattered light. The degree of scattering is proportional to the concentration and size of suspended solid particles in the liquid. The sensor processes the detected scattered light to calculate the concentration of total suspended solids in the sample.

TSS measurement results are typically displayed on a screen or provided as an electrical signal.

The turbidity sensor can work normally even in liquids with high turbidity levels, such as aquaculture, industrial wastewater treatment, water eutrophication treatment and other places where turbidity in liquids needs to be monitored.

How to choose the best turbidity sensor?

How to choose the best turbidity sensor for different measuring points? You need to correctly analyze the properties of the sample to be measured, understand the environment in which the sensor needs to work for a long time, and clearly understand the accuracy of the sensor required and your budget. Hopefully these considerations will help you choose the right turbidity sensor:

Measure Range

Consider the range of turbidity values you need to measure. Ensure that the sensor’s measurement range covers the expected turbidity levels in your sample. Some sensors are designed for low turbidity levels, while others are suitable for high turbidity levels.

Accuracy

Accuracy is crucial, especially for applications that require precise turbidity measurements. Look for a sensor with high accuracy. Renke RS-ZD-N01-* turbidity sensor has a built-in temperature compensation function, which avoids the influence of solution temperature changes on the measurement results. The monitoring results are more accurate.

Calibration

Check whether the sensor requires calibration and what calibration standards are needed. Calibration ensures measurement accuracy. Some sensors may require calibration using known turbidity standard solutions.

Application

Consider the nature of your sample. For instance, if your sample contains large particles, choose a sensor that can handle these particles without clogging or interference.

Environmental Conditions

It is also important to consider the operating environment of the sensor. For example, specific sensors should be selected for measuring points with harsh environments, and sensors with temperature compensation should be selected for places with large temperature changes. Only in this way can the measured data have reference significance.

Response Time

Although most measurement sites do not have high requirements for sensor response time, in some sites that require real-time data to control the production process, a fast response time can better promote production.

Maintenance

Choosing a turbidity sensor that is easy to maintain or has automatic cleaning capabilities will not only save time, but also significantly reduce maintenance costs.

Budget

Currently, there are many types of turbidity sensors with varying prices. Budget is a consideration but by no means the most important. Therefore, when purchasing a turbidity sensor, while ensuring accuracy and stability, reduce the budget by screening out unnecessary other functions.

In addition to these, brand, data platform, and installation method are factors that need to be considered. Renke is a professional water quality sensor manufacturer. If you have any questions, contact us now.