As an advanced and well-known technology, ultrasonic sensor is widely used in various consumer and industrial fields. When adding distance measurement or detection functions to products, ultrasonic sensor is a good choice. In addition, it has wider applicability and higher reliability in hardware upgrades and software adaptations.

What is an ultrasonic sensor?

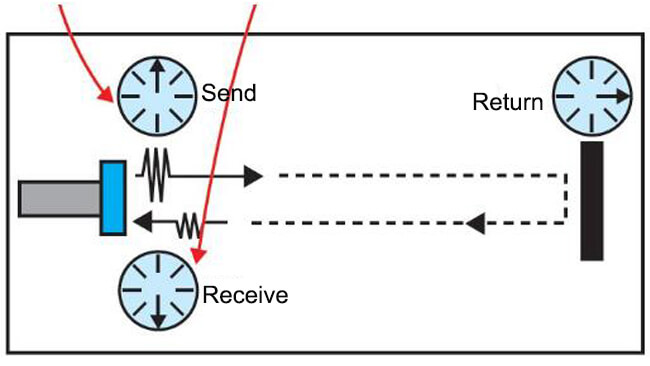

An ultrasonic sensor is an electronic device. It emits ultrasonic waves and converts the reflected sound into an electrical signal to determine the distance of a target item. Ultrasonic waves travel faster than audible sound (i.e. sound that humans can hear). The two main components of an ultrasonic sensor are a transmitter that uses piezoelectric crystals to generate the sound and a receiver that receives the sound after it has traveled to and from the target.

They are primarily used for distance measurement. They can be found in cars’ self-parking technology and collision avoidance safety systems. In addition to robotic obstacle detection systems, ultrasonic transmitters are also used in manufacturing technology. Compared to infrared (IR) sensor in proximity detection application, the ultrasonic sensor is less susceptible to interference from smoke, gas, and other particulate matter (although the physical components are still affected by variables such as heat).

It is also used as level sensor in closed container to detect, monitor, and manage liquid levels, such as vats in chemical plants. Most notably, ultrasonic technology enables the medical community to create images of internal organs, detect malignancies, and monitor the health of newborns in the womb.

How does ultrasonic sensor work?

Ultrasonic sensors work by emitting sound waves at frequencies above the human hearing range. To receive and send ultrasonic waves, the sensor’s transducer acts as a microphone. Like many other sensors, ultrasonic sensors use a single transducer to send a pulse and receive an echo. The sensor calculates the distance to the target by measuring the time that elapses between sending and receiving the ultrasonic pulse. It sends out a 40kHz ultrasonic pulse that travels through the air and bounces back to the sensor if it encounters an obstacle or object. The distance can be estimated by multiplying the propagation time by the speed of sound.

Ultrasonic sensors are a excellent solution for detecting transparent objects. For example, infrared sensors are difficult to use for special occasions for level measurement because the target is translucent.

They have difficulty detecting the presence of objects regardless of color, surface, or material (unless the material is very soft like wool, as it absorbs sound.)

It is an trusted solution for detecting translucent objects and other objects that optical methods cannot measure.

Where is ultrasonic sensor generally used?

Liquid level sensing is one of the applications that utilizes ultrasonic technology the most. Because it can detect liquids of any hue or opacity while remaining contactless. The second is general object detection, which has the advantage of its low cost and simplicity. For example, vehicle collision avoidance detection, presence detection, box sorting, forklift pallet detection, beverage bottle counting, and other applications.

Advantages and disadvantages

Advantages

1. Not affected by the color or transparency of the object

Because ultrasonic sensors reflect sound off the object, the color or transparency of the object will not affect the sensor’s readings.

2. Can be used in low-light conditions

Unlike proximity sensors that use infrared light, dark settings have little effect on the detection capabilities of ultrasonic sensors.

3. Not affected by dust, dirt, or high humidity levels

While many sensors perform well in these conditions, others can produce inaccurate readings, especially in conditions where there is a lot of dust or moisture accumulation.

4. High accuracy in certain applications

Ultrasonic transmitters have high accuracy when measuring thickness and distance between parallel surfaces.

5. Penetration

The high sensitivity and penetration of ultrasonic sensors make it easier to detect external environments as well as objects at depth.

6. Strong anti-interference ability

It is very resistant to environmental influences and can be used in any lighting environment. It has reliable performance in a variety of lighting settings, including indoors, outdoors, and complex ambient light. Because ultrasonic transmitters are not affected by smoke or dark matter and can detect light, smoke, dust, color, materials, etc., they are superior to infrared sensors in a variety of applications.

7. Wide range of applications

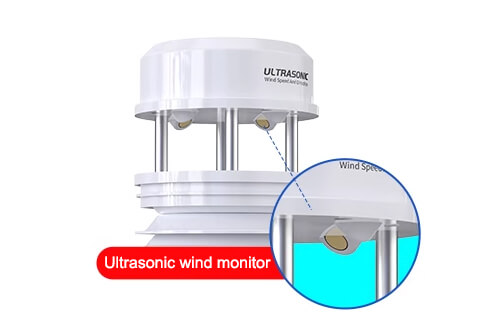

Ultrasonic sensors can be used in a variety of applications, such as water level sensor, ultrasonic wind sensor, automatic weather station, distance detection applications, etc.

8. Multi-purpose

Detection of presence, detection of level, detection of position, detection of distance, etc. It can meet the needs of most non-contact detection applications.

Disadvantages

1. Cannot work in a vacuum

Since the sensor rely on sound to function, it cannot function in a vacuum because there is no air for sound to travel through.

2. Not suitable for use underwater

3. Soft materials will have an impact on sensor accuracy

Objects wrapped in soft fabrics will absorb more sound waves, making it difficult for the sensor to see the target.

4. Temperature changes of 5-10 degrees Celsius or more will affect sensor accuracy

However, many manufacturers’ devices now include temperature correction features. These sensors are calibrated based on changes in temperature or voltage before use.

5. Small objects have a hard time reflecting sound waves

An object may be too small to reflect enough sound waves to the sensor to detect.

6. It is difficult to capture reflected waves of certain shapes.

Ultrasonic sensor limitations

Ultrasonic sensors, such as the HC-SR04, can measure distances up to 400 cm with a tolerance of 3 mm. However, if the target is placed in such a way that the ultrasonic signal is deflected rather than reflected by the ultrasonic sensor, the measured distance may be wrong. In some cases, the target object is too small and the reflected ultrasonic signal is not enough to identify it and accurately determine the distance.

In addition, things such as fabrics and carpets can absorb auditory impulses. If the signal is absorbed at the end of the target object, it cannot be reflected by the sensor, so the distance cannot be recorded.

The high sensitivity of ultrasonic sensor makes it efficient, but problems can also occur. For example, the sensor can identify waves that are interfered by air conditioning systems and false signals from ceiling fans.

Ultrasonic sensors can detect items within their range, but cannot distinguish between shapes and sizes. However, this limitation can be circumvented by using two sensors instead of one. The two sensors can be mounted next to each other. The shape and size of the target can be determined by examining the overlapping shadow areas.

FAQs

Four types. There are four types of the ultrasonic sensor, classified by frequency and shape: drip-proof, high-frequency, and open-structure (lead and patch).

First, 5-Piece Ultrasonic Sensor Module Kit HC-SR04 Distance Sensor with 3-Piece Mounting Bracket Compatible with Arduino UNO Mega R3 Mega2560 Duemilanove Nano Rapsberry Pi 3 Robot XBee ZigBee. Second, Waterproof Ultrasonic Module JSN-SR04T Arduino Waterproof Integrated Distance Sensor.

Speaker grill cloth, wire mesh, and open-cell foam are ways to protect sensor. For proper operation, humidity, temperature, and echo must be considered when using the sensor.

When multiple sensors are operating in the same space, interference will occur in the reported range. Since the sensors are not synchronized, the range of the sensors will be at slightly different intervals. For most applications, these frequency drifts will cause interference between sensors.

The more accurate ultrasonic sensor can achieve 0.1-0.2% of the detection range under perfectly controlled conditions, and most good ultrasonic sensor can generally achieve 1% to 3% accuracy.

The ultrasonic sensors are suitable for close-range detection up to ten meters and can provide multiple range measurements per second.

Ultrasonic sensors use ultrasonic waves to measure distance. The sensor head transmits ultrasonic waves and receives the waves reflected back from the target. The ultrasonic sensor measures the distance to the target by measuring the time between transmission and reception.

The IoT ultrasonic sensor is designed for contactless detection of solids and liquids. These sensors are used for a variety of functions, from monitoring water levels in tanks to fluid identification to detecting object proximity.